THE LIOEXTRACTION PROCESS

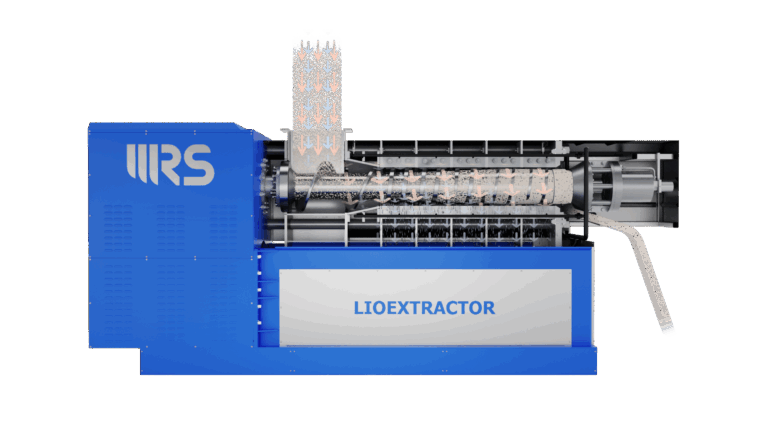

The WRS Lioextractor mechanically presses and dehydrates all types of compressible materials — including woody biomass, pulper waste, biogas digestate, compost, treatment residues, agricultural waste, and FORSU.

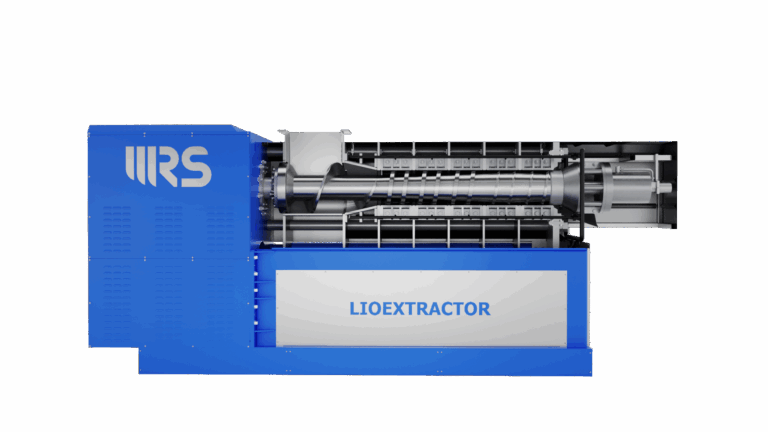

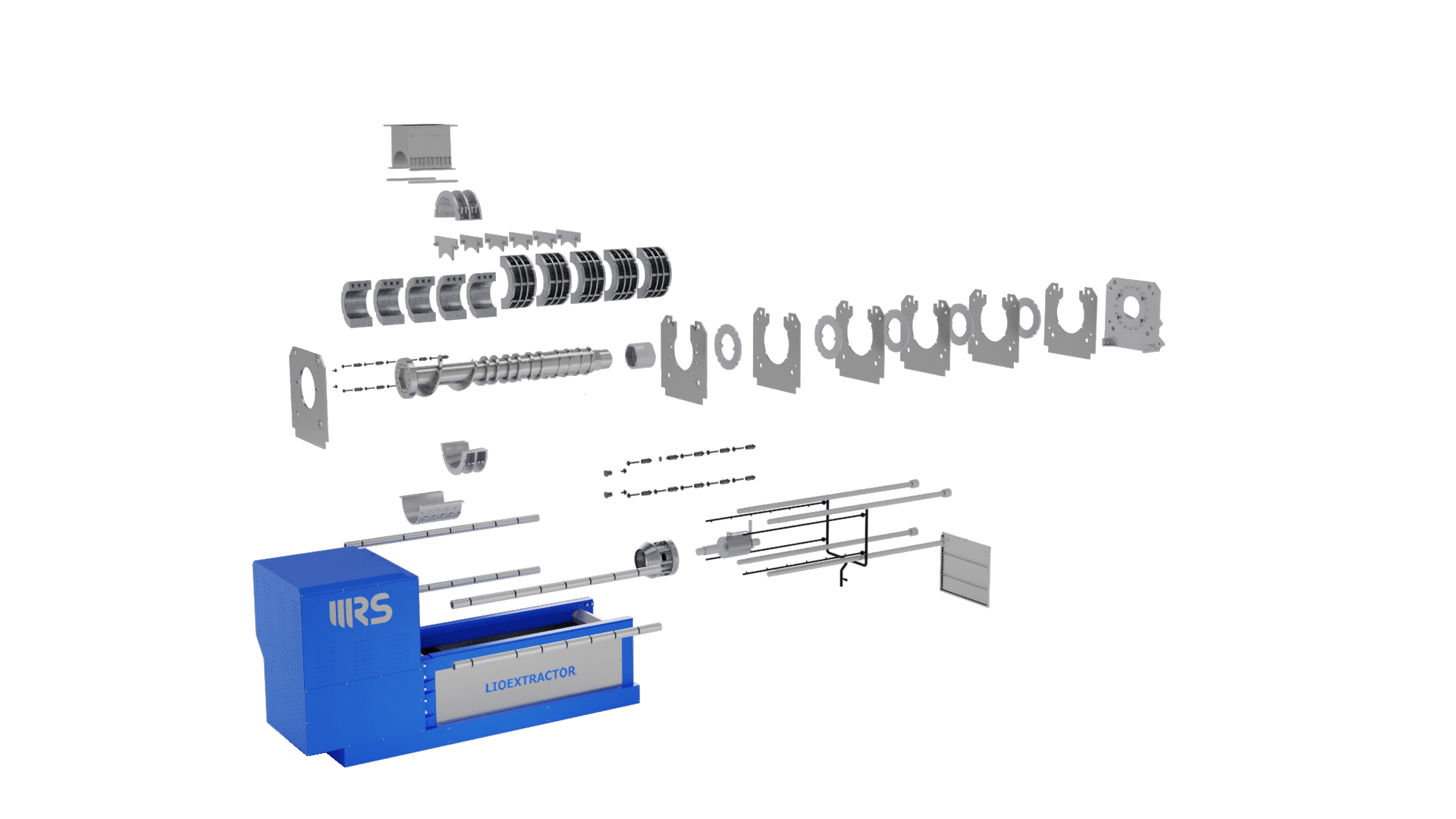

Main Components

- Pressing system with a discontinuous-pitch compression screw and two half-shell filter modules for quick and easy replacement;

- Control unit with an electric motor and a transmission system comprising a gearbox and V-belts;

- Hydraulic system with a power unit for counter-thrust regulation;

- Electrical system with PLC-based control panel, protections, and safety devices compliant with current regulations;

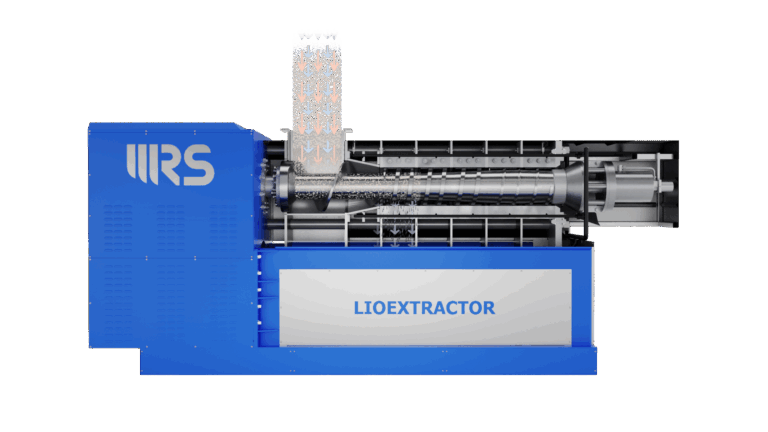

- Automatic washing system to keep all filtering surfaces clean;

- Liquid collection tank for process management.

FIELDS OF APPLICATION

The WRS Lioextractor can be effectively used in:

- Paper mill pulper waste

- Biogas digestate

- Waste treatment residue

- Woody biomass

- Agricultural by-products

- Compost

- FORSU

MAIN ADVANTAGES

By choosing the WRS SW500/6 Lioextractor, you can benefit from:

LOWER OPERATING COSTS,

thanks to reduced material weight, volume, and transport needs

HOMOGENEOUS, OPTIMIZED OUTPUT,

producing a liquid fraction and a highly dehydrated, shredded solid fraction — ideal for transport, reuse, and energy recovery;

INTEGRATED AUTOMATION,

with intelligent control systems adapting to input material characteristics;

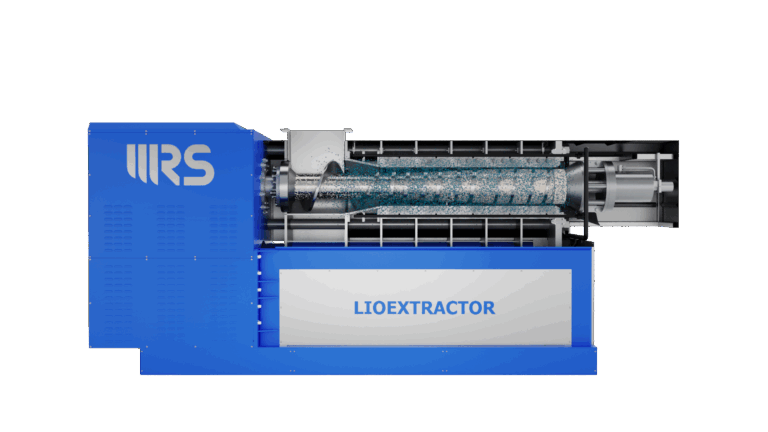

INNOVATIVE COMBINED DEHYDRATION AND CRUSHING SYSTEM

achieving minimal residual moisture and maximum volume reduction;

ADVANCED MONITORING SOFTWARE,

managing outlet moisture and coordinating motor load with hydraulic counter-pressure;

AUTOMATIC FILTER WASHING SYSTEM,

maintaining high discharge efficiency over time;

QUICK AND EASY MAINTENANCE,

with simplified disassembly of filters and compression screws, minimizing downtime.

FOCUS: BENEFITS FOR AGRICULTURE AND BIOGAS

The Lioextractor is particularly effective in the agricultural and biogas sectors, thanks to its high-efficiency solid-liquid separation of digestate, which optimizes nutrient recovery and reduces operating costs.

Key benefits include:

- Improved storage management;

- Enhanced transport efficiency due to reduced volume and weight;

- Lower soil compaction during field application;

- Optimized agronomic use, allowing for more precise and sustainable nutrient distribution;

- Reduced greenhouse gas emissions during storage and spreading;

- Promotion of circular economy practices, enabling nutrient recycling within agricultural cycles;

- Improved soil quality, enhancing structure, fertility, and water retention;

- Better animal welfare, as the solid fraction (with ~45% residual moisture) provides dry, comfortable bedding that reduces infection risk;

- Odor reduction, improving environmental quality and facilitating use even near urban areas.